Parts of Sunglasses: A Complete Beginner’s Guide

Most people focus only on style and price when buying sunglasses, but the real difference between a great pair and a disappointing one comes down to the quality and design of individual parts. From the lens coatings that protect your eyes to the tiny screws that hold everything together, each component plays a crucial role in comfort, durability, and performance.

In this guide, we’ll break down every part of sunglasses in simple terms, explain what makes each component work well, and give you practical tips for choosing your sunglasses. By the end, you’ll be able to spot quality construction and make informed decisions that matter.

Contents

Understanding the Main Parts of Sunglasses

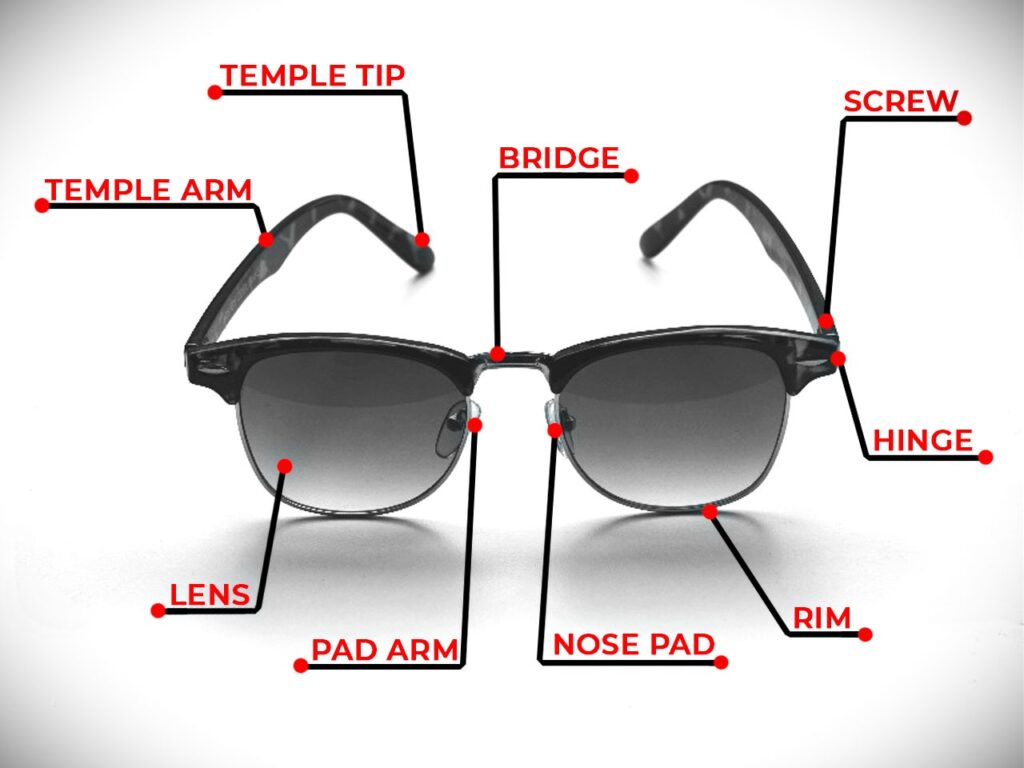

Think of sunglasses as a carefully engineered system with four main areas: the lens assembly, frame structure, hardware connections, and comfort features. Each area contains multiple parts that must work together seamlessly.

- Lens assembly – includes not just the lenses themselves, but also the coatings, treatments, and mounting systems that keep them secure

- Frame structure – consists of the front frame that holds the lenses and the temple arms that rest on your ears

- Hardware connections – the hinges, screws, and small metal parts that allow the sunglasses to fold and adjust

- Comfort features – include nose pads, temple tips, and ergonomic design elements that make wearing them pleasant for hours

Understanding these four systems helps you identify where problems might occur and what to look for when shopping. A weakness in any one area can make even expensive sunglasses uncomfortable or short-lived.

Sunglasses Lens System

Lens Materials That Actually Matter

The material of your lenses affects everything from clarity to durability. The four main options are glass (best clarity but heavy), polycarbonate (impact-resistant and lightweight), CR-39 plastic (balanced performance), and Trivex (premium lightweight option).

Each material has specific advantages for different activities and budgets. For a detailed comparison of lens materials, including performance specs and price ranges, check out our comprehensive guide on sunglasses lens materials.

Lens Coatings and Treatments

The coatings on your lenses often matter more than the base material. Key coatings include anti-reflective (reduces glare), scratch-resistant (extends lens life), UV coating (essential for eye protection), polarized film (cuts glare from reflective surfaces), and mirror coatings (aesthetic and privacy).

These treatments work together to enhance performance, durability, and comfort. For detailed information about each coating type, benefits, and which combinations work best for different activities, read our complete guide on sunglasses lens coatings and treatments.

Lens Shape and Optical Performance

The base curve of a lens affects both comfort and vision. Flatter curves (lower base numbers) work better for driving because they reduce distortion at the edges. Curved lenses (higher base numbers) provide better coverage and peripheral protection but may cause distortion for some people.

Wrap angle determines how much of your peripheral vision is covered. Sports sunglasses typically have aggressive wrap angles for maximum protection, while fashion frames use minimal wrap for a more flattering appearance.

Lens thickness affects both optical quality and weight. Thicker lenses generally provide better optics but add weight. Quality manufacturers balance these factors based on the intended use.

Sunglasses Frame Structure

Sunglasses frames are typically made from plastic materials (acetate, TR90, injection-molded plastic) or metals (titanium, stainless steel, aluminum). The choice of material affects weight, durability, and comfort, but the frame construction and individual parts determine how well your sunglasses fit and function.

Sunglasses Frame Parts Breakdown

Front frame – holds the lenses and determines the overall shape and style. Quality frames have consistent thickness and smooth edges. Check for symmetry by looking at the frame straight-on – uneven construction is immediately obvious.

Bridge – connects the two lens areas and rests on your nose. Three main types:

- Keyhole bridges distribute weight evenly and suit most face shapes

- Saddle bridges spread the load across more of your nose but may slip on narrow bridges

- Adjustable bridges allow customization but add complexity

Temple arms – the sides that go over your ears must be the right length and curve. Standard temple length is 135-145mm, but this varies by head size. The curve should follow your head’s natural contour without creating pressure points.

Hardware and Hinges: The Moving Parts of Sunglasses

Hinge Types and Their Trade-offs

- Barrel hinges are the traditional standard, using interlocking metal cylinders held together by a screw or pin. Five-barrel hinges are stronger than three-barrel versions but add weight. Look for smooth operation without play or binding.

- Spring hinges allow the temple to flex outward beyond the normal opening angle. This prevents breakage when the frames are stretched and accommodates larger heads. Quality spring hinges maintain tension over thousands of cycles.

- Screwless hinges use clips, pins, or other mechanisms instead of traditional screws. They’re harder to repair, but eliminate the most common failure point in sunglasses. Some premium brands use proprietary screwless designs.

- Wraparound hinges allow extreme temple angles needed for sports frames. They’re more complex but essential for sunglasses that curve around your head.

Small Sunglasses Parts That Make a Big Difference

- Screws seem insignificant but determine long-term reliability. Quality frames use corrosion-resistant screws that won’t seize or strip. Keep a small screwdriver handy for periodic tightening – loose screws are the most common sunglasses problem.

- Washers and spacers fine-tune the fit between parts. They prevent metal-on-metal contact that causes wear and allow adjustment for different head sizes.

- End pieces connect the temples to the front frame. They’re a common stress point, so quality construction is essential. Look for substantial metal end pieces even on plastic frames.

- Lens clips on interchangeable-lens systems must hold securely without being difficult to operate. Test the mechanism before buying – it should feel solid and precise.

Comfort-Enhancing Parts of Sunglasses

Nose Support Systems

Nose pads can make or break comfort. Silicone pads grip better and feel softer than hard plastic, but they attract dirt and may discolor over time. Adjustable pads let you customize the fit, while fixed pads are more durable but less adaptable.

Nose bridges on plastic frames distribute weight differently than pad systems. They work well for average nose shapes but can’t be adjusted much. The bridge should contact your nose evenly without pinching.

Pad arms (the metal pieces that hold adjustable nose pads) bend to change the angle and position of the pads. Quality pad arms maintain their adjustment over time and resist corrosion.

Temple Comfort Elements

Temple tips (the parts that go behind your ears) determine how securely the sunglasses stay in place. Rubber tips provide the best grip but may pull hair. Silicone tips offer a good compromise between grip and comfort.

Temple curves should match your head shape. Asian fit frames have different curves than standard Western fits. The temples should follow your head’s contour without creating pressure points.

Adjustable features like bendable temple tips and sliding nose pads allow customization. More adjustment capability usually means better comfort but also more complexity.

Specialized Comfort Additions

Cable temples wrap around your ears for security during sports. They’re common on safety glasses and fishing sunglasses, where losing them would be problematic.

Strap attachments let you secure sunglasses around your neck. Most quality frames have small holes or slots for aftermarket straps.

Cushioning like foam inserts creates a gasket effect for motorcycle and extreme sports applications. It blocks wind and dust but adds bulk.

Quality Indicators: Key Factors to Consider in Sunglasses Parts

Construction Quality Signs

Hinge operation should be smooth and consistent. Open and close the temples repeatedly – quality hinges feel solid without binding or looseness. Spring hinges should return to position crisply.

Frame alignment affects both appearance and comfort. Hold the sunglasses at arm’s length and check that both lenses are level and the temples are symmetric. Poor alignment causes uneven weight distribution.

Lens mounting should be secure with no gaps between lens and frame. Push gently on the lenses – they shouldn’t flex or move in their mounting.

Finish quality reflects overall manufacturing standards. Look for smooth surfaces, consistent coloring, and clean edges. Rough or unfinished areas indicate rushed production.

Durability Markers

Material thickness should be adequate without being bulky. Thin sections will break under stress, while excessive thickness adds unnecessary weight.

Reinforcement areas at stress points like hinges and bridge areas show thoughtful engineering. Quality frames have thicker material where forces concentrate.

Hardware quality is visible in the screws, hinges, and small parts. Stainless steel or titanium hardware resists corrosion better than brass or aluminum.

Making Informed Choices

Understanding sunglasses parts transforms you from a passive consumer into an informed buyer. You now know why some sunglasses cost more than others, what features actually matter for your needs, and how to maintain your investment properly.

The next time you shop for sunglasses, examine the hinges, test the nose pad adjustment, and ask about lens coatings. Check the frame material and construction quality. These details determine whether your sunglasses will be a joy to wear or a constant source of frustration.

Your eyes deserve protection, and now you have the knowledge to choose sunglasses that provide it effectively and comfortably for years to come.